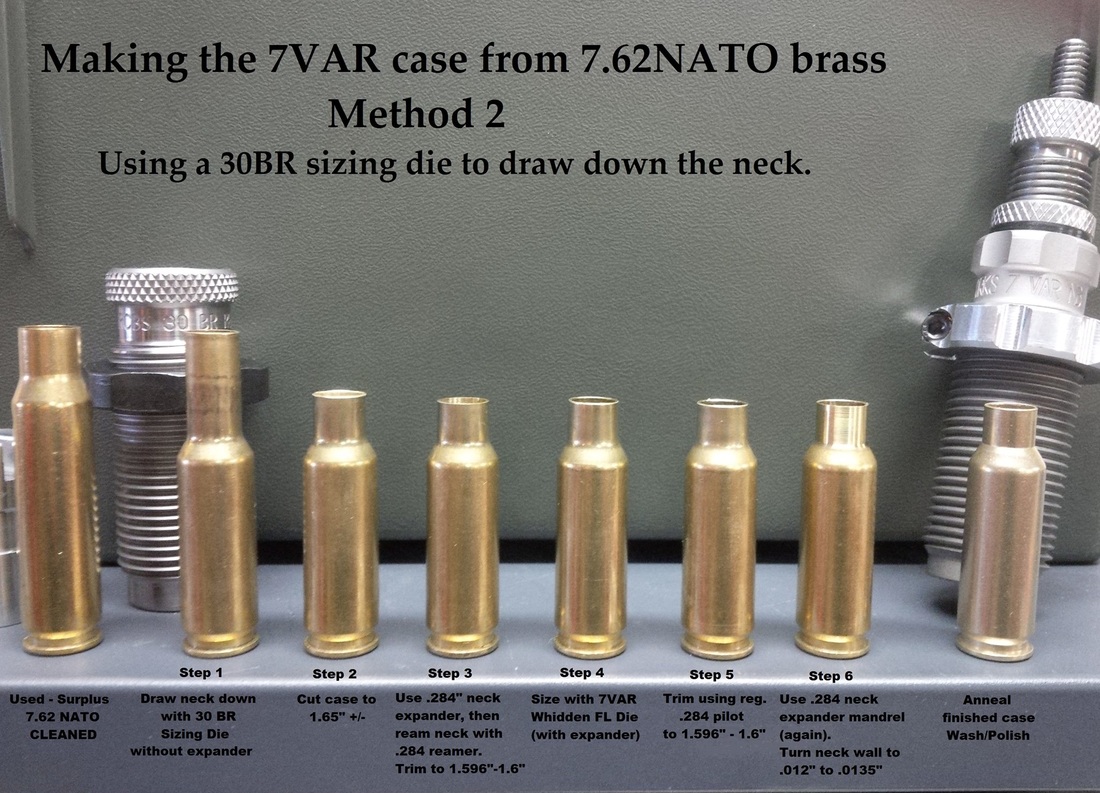

Method 2 by Keith Barker:

Update in reference to making 7VAR brass from 7.62NATO cases using a 30BR die to draw the cases down.

I finally got a chance to make a lot of 7VAR using the 30BR sizing die to draw the neck down, and I can tell you that this works real nice.

This is my process:

1. mount the 30BR die (I'm using RCBS) off the top of the shell plate around .200" or so and draw down the 7.62 case. Note: no annealing first now seams to work better.

2. Cut to length with chop saw and deburr.

3. Expand case mouth with .284 expander mandrel (I'm using the 21st Century Mandrel).

4. Ream with .284 reamer and trim to desired case length.

5. Size with 7VAR Whidden die w/expander inserted.

6. Expand again with .284 expander mandrel if using the 21st Century Lathe for neck turning.

7. Trim again with smooth trimming pilot.

8. Neck turn.

9. Anneal, wash/polish.

Notes: I noticed much less neck tension while neck turning, making the process a bit smoother.

I finally got a chance to make a lot of 7VAR using the 30BR sizing die to draw the neck down, and I can tell you that this works real nice.

This is my process:

1. mount the 30BR die (I'm using RCBS) off the top of the shell plate around .200" or so and draw down the 7.62 case. Note: no annealing first now seams to work better.

2. Cut to length with chop saw and deburr.

3. Expand case mouth with .284 expander mandrel (I'm using the 21st Century Mandrel).

4. Ream with .284 reamer and trim to desired case length.

5. Size with 7VAR Whidden die w/expander inserted.

6. Expand again with .284 expander mandrel if using the 21st Century Lathe for neck turning.

7. Trim again with smooth trimming pilot.

8. Neck turn.

9. Anneal, wash/polish.

Notes: I noticed much less neck tension while neck turning, making the process a bit smoother.

RSS Feed

RSS Feed