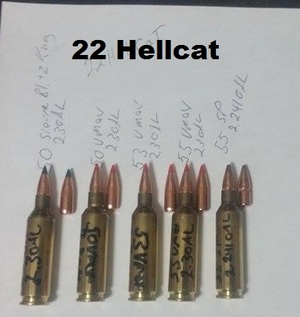

This week thought I would talk about what i am working on now. I just got in the first barrels of my latest wildcat round I designed the 22 Hellcat. The Hellcat came about when a couple of us got to talking and really wanted a 22-250 in an AR. I wanted to do a simple cat for once that didn't require a lot of brass work so I started messing with cases and numbers.

After running some numbers and making a few dummy rounds to see how bullets fit in the case I ran my conclusions by the guys. After a bunch of discussion I pooled the ideas and came up with the Hellcat. No the Hellcat isn't really all new in basic form it has been done in the 22x47 lapua but the case was too long to fit in the AR magazine so I decided to trim the case to 1.8 inches and make the round for light bullets only. So if you can find 22x47 lapua dies they will work for this cat.

The Hellcat is a 6.5x47 lapua case necked down to .224 and then trim the case to 1.8 inches that is it. just neck down and trim. Shoulder position is in the same place as the 6.5x47 no neck turn or ream. That makes this a very simple wildcat that anyone can enjoy. It is maxing out the case and AR magazine but it will fit 65 grain sierra bullets on down.

Performance estimates put it just ahead of the 22-250 but i will be happy with 22-250 performance. Case capacity is 46.3 grains on fresh formed brass which puts it about 2 grains more than most 22-250's

After running some numbers and making a few dummy rounds to see how bullets fit in the case I ran my conclusions by the guys. After a bunch of discussion I pooled the ideas and came up with the Hellcat. No the Hellcat isn't really all new in basic form it has been done in the 22x47 lapua but the case was too long to fit in the AR magazine so I decided to trim the case to 1.8 inches and make the round for light bullets only. So if you can find 22x47 lapua dies they will work for this cat.

The Hellcat is a 6.5x47 lapua case necked down to .224 and then trim the case to 1.8 inches that is it. just neck down and trim. Shoulder position is in the same place as the 6.5x47 no neck turn or ream. That makes this a very simple wildcat that anyone can enjoy. It is maxing out the case and AR magazine but it will fit 65 grain sierra bullets on down.

Performance estimates put it just ahead of the 22-250 but i will be happy with 22-250 performance. Case capacity is 46.3 grains on fresh formed brass which puts it about 2 grains more than most 22-250's

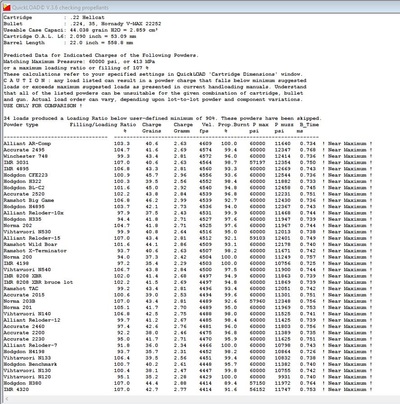

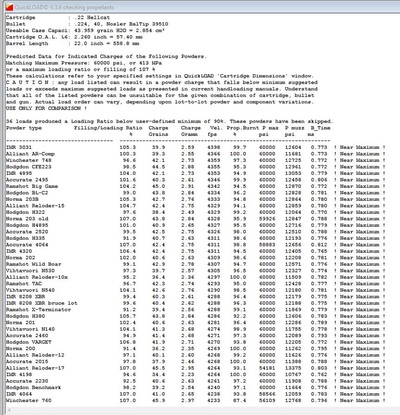

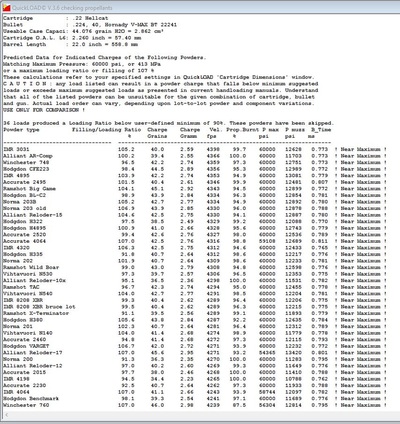

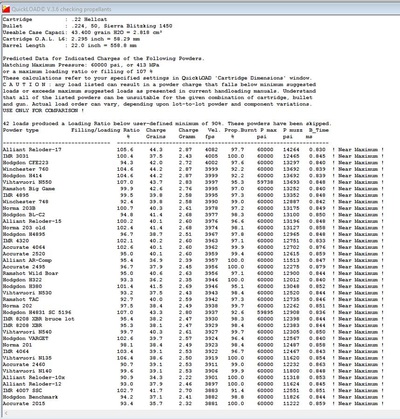

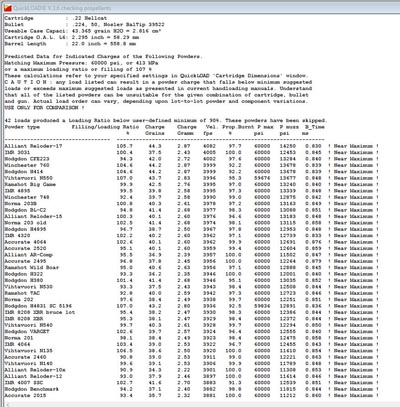

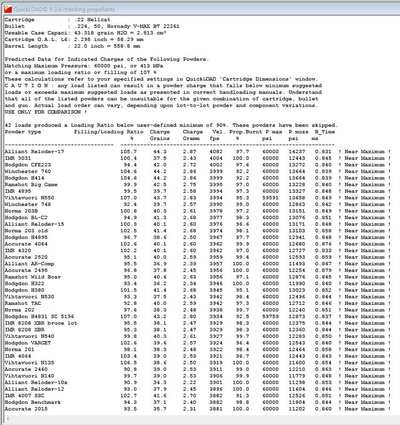

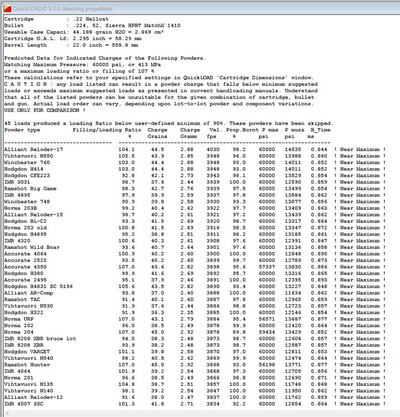

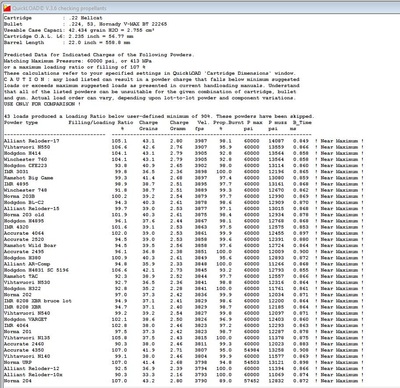

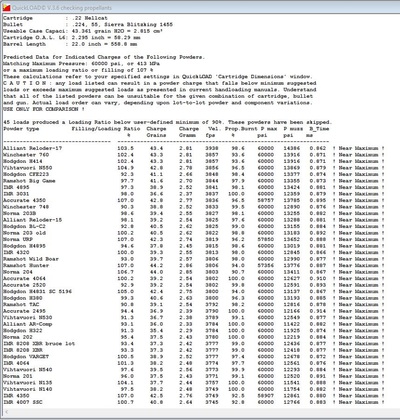

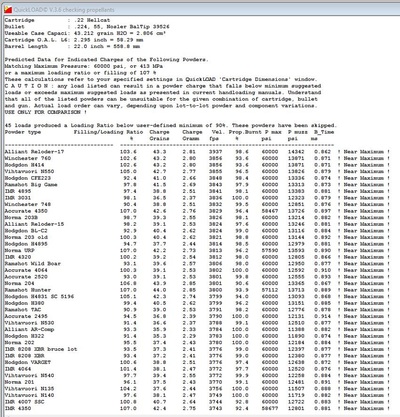

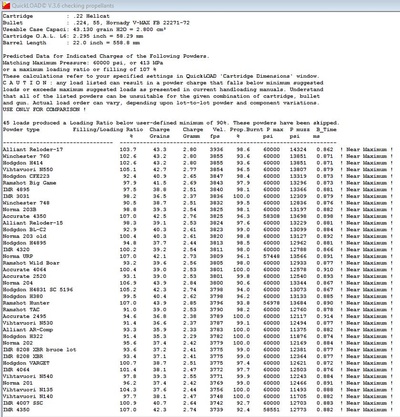

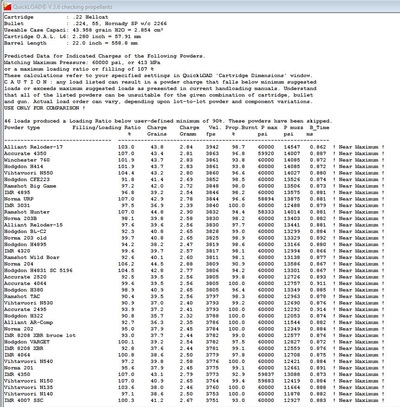

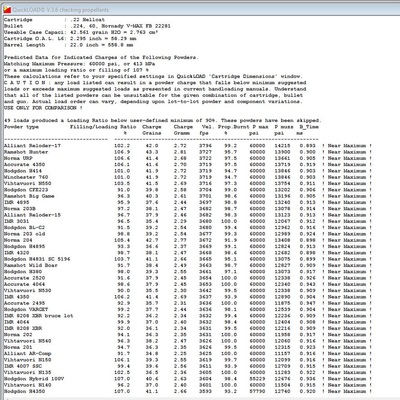

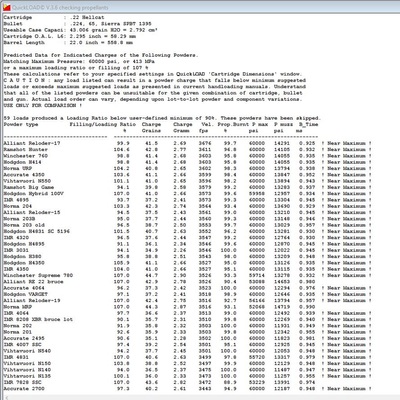

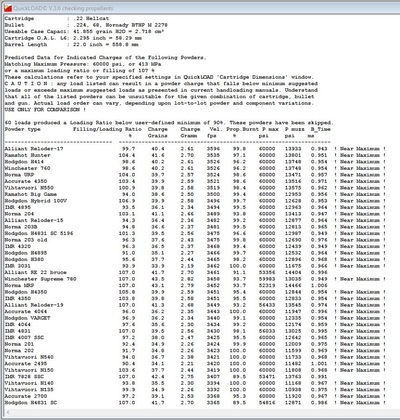

Below are the performance estimates for a 22 inch barrel.

In the first batch of barrels we have 6 22 inch and 1 20 inch with half 10 twist and half 12 twist. If staying 55 grain and under the 12 twist is just fine I wanted to test the 65's so I got a 10 twist.

With the overbore status of this round I don't expect great barrel life. It should be on par with the 22-250 but the flat out performance for the AR15 on varmints will be worth it.

In the first batch of barrels we have 6 22 inch and 1 20 inch with half 10 twist and half 12 twist. If staying 55 grain and under the 12 twist is just fine I wanted to test the 65's so I got a 10 twist.

With the overbore status of this round I don't expect great barrel life. It should be on par with the 22-250 but the flat out performance for the AR15 on varmints will be worth it.

RSS Feed

RSS Feed